Brick masonry is one of the basic units of building construction. Hence due care must be given while constructing the brick masonry.

The field engineers should have a good knowledge of the construction practices and techniques so that brick masonry effectively serves the purpose for which it is intended.

This article is designed in a way such that not only engineers even a homeowner can understand the basic rules that should be followed while constructing brickwork.

How to check the quality of bricks at the construction site?

The quality of the brick masonry depends upon the quality of materials used while construction.

Good quality bricks are the prerequisite for constructing a good brick masonry wall.

Here are some tests to determine the quality of bricks at the site.

1) The bricks should be hard, durable, and uniform in size and shape.

2) The edges of the brick should be sharp and straight without any damage.

3) The bricks should be free from any white salt deposits on the surface.

4) The bricks should not be overburnt or underburnt. It should have a uniform deep red color without any color change.

5) The bricks should not break into pieces when dropped from a height of 1m.

6) If two bricks are made to collide with each other, it should make a metallic sound, If it is a good quality brick.

7) The surface of the brick should not be too smooth which results in slippage of mortar.

8) When scratched by a finger no impression should be made on the surface of the brick.

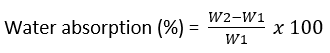

9) The bricks should not absorb water more than 20% of their dry weight when immersed in water for 24 hours at 27°C. Take the weight of the dry brick as W1. Immerse the brick in water at 27°C for 24 hours. Now take the brick and wipe out the excess surface moisture and take the weight of the brick as W2.

10) If you think the dimension of the brick drastically varies from one another, then we can easily check the dimension in the field.

Randomly choose 20 bricks from the unit. Measure the length and width of one brick.

Now, let’s assume the length of the brick as 190mm and the width of the brick as 90mm.

Place those 20 bricks lengthwise and measure the overall length. If all the bricks are of the same dimension, then the overall length should be 20×190 = 3800mm. However, it is not always of the same dimension, in that case, the acceptable tolerance is ± 80mm i.e the overall length may be in the range of 3720 – 3880 mm.

Now do the same process width-wise.

Place those 20 bricks widthwise and measure the overall width. If all the bricks are of the same dimension, then the overall width should be 20×90 = 1800mm. However, it is not always of the same dimension, in that case, the acceptable tolerance is ± 40mm i.e the overall length may be in the range of 1760 – 1840 mm.

The height tolerance is also the same as that of the width tolerance.

Read the below article to know about the tests that are performed to assess the quality of cement at the site.

How to check the quality of cement at the construction site?

General guidelines for brick masonry construction

The following points are to be considered while supervising/constructing brick masonry work.

1) A sound, hard, well-burnt brick should be used in constructing a brick wall. It should also have a uniform color, size, and shape.

2) The bricks should be properly soaked in water for at least 2 hours before use. So that it will not absorb moisture from the mortar.

3) The bricks should be laid on their course with their frogs pointing upwards.

4) The brick course must be truly horizontal and the vertical joints in the alternate courses should be vertically above each other.

5) If you are constructing adjacent walls, then both brick walls should be raised uniformly with proper bond. The maximum difference in the rise of the walls should not be more than 1m.

6) The height of the brick masonry constructed in a day shall not be more than 1.5m.

7) The use of brickbats in construction should be discouraged except in situations where it becomes absolutely necessary.

8) If it is planned to extend the length of the currently constructed wall in the future, then in order to ensure the continuous bond between the old and new wall, the current wall should be stopped with the tooth end.

9) The verticality of the brick wall should be checked using a plumb bob on a regular intervals.

10) In order to carry out the brick masonry at higher levels, generally single scaffolding is provided. But if possible, it is best to provide Double scaffolding.

Because the single scaffolding may result in leftover holes in the masonry which was later fixed, but this may cause joint cracks and may result in unwanted seepage of water into the structure.

11) The thickness of mortar joints in between the bricks shall be in the range of 10 – 15mm. Higher thickness may result in higher shrinkage and leads to some serious cracks in the brick wall.

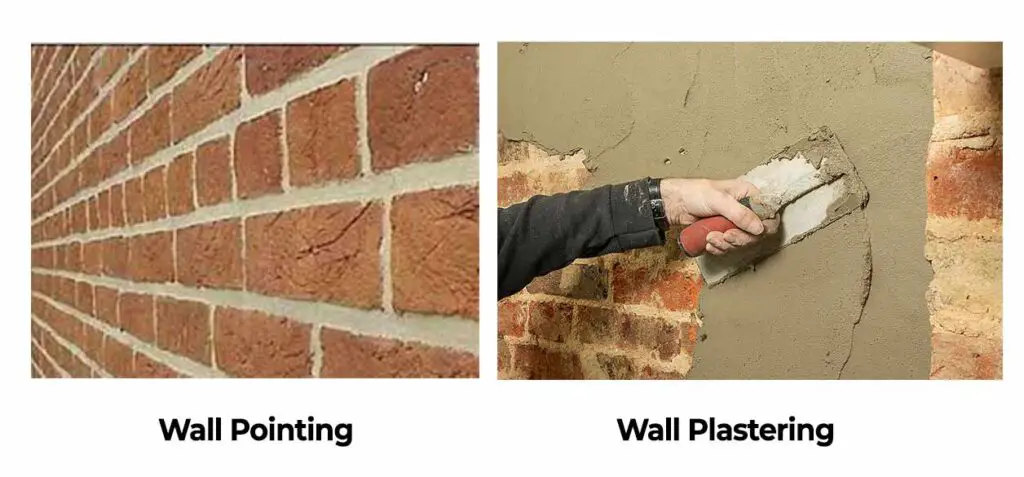

12) If you are planning to plaster the brick wall, then it is recommended to wait for at least 28 days after the completion of the brickwork.

Because in the early stages, the mortar is prone to shrinkage cracks. So the time gap allows the mortar to undergo optimum shrinkage before plastering is carried out.

13) In the case of pointing works, no such time gap is required, the mortar joints should be finished while laying the bricks itself.

14) The finished brickwork must be kept hydrated for,

- Minimum 1-2 weeks, if cement mortar is used

- Minimum 2-3 weeks, if a lime mortar is used

Whatever the situation, it should not be less than 7 days.

15) The water used for preparing brick mortar and curing also plays an important role. The water should be potable and free from any salts.

It is recommended to create a checklist of the above things on your phone or paper while supervising/ constructing a brick wall.

Brick masonry walls constructed by these guidelines will largely reduce the cost of repairing at the later stages.

Hope you understand everything you need to know about the brick masonry guidelines and checks. If you find this article helpful (or) If you have any queries, let us know in the comment section.

Read more:

How to calculate the quantity of cement and sand required for plastering?

You have a knack for making even the most complex subjects accessible and interesting.

Your article was a real eye-opener for me. The clarity and precision in your writing are commendable.