Cement is one of the most widely used construction materials all around the world. Hence it is necessary to check the quality of cement before beginning any projects. No doubt, several tests have been done at the factory itself before the product comes out but sometimes there may be a high probability that it may go bad during transportation or storage.

Hence, the cement should be subjected to field tests when it is used for minor works. However, for important works, it is always advisable to test the cement in the laboratory to make sure it possesses sufficient physical and chemical characteristics. Click here to know more about the laboratory tests of cement.

The various field tests which can be performed are listed below,

1.Presence of lumps test

Open the cement bag and take a good look at the cement. Observe if there are any lumps in the bag.

If there are no lumps, then we are good to go.

If there are any lumps in the bag, it shows that the cement absorbs moisture from the atmosphere and began its chemical reaction (Hydration). Using this cement may lead to a loss of strength. Hence either the cement should be subjected to laboratory tests or should be rejected.

2.Colour test

The cement should be uniform in colour. Normal cement should have a grey colour with a little greenish shade, it is often called Greenish grey.

Any cement which shows another colour indicates that there is a fault in the production like disproportion of ingredients or high degree of burning etc. These cement should be subjected to lab tests.

3.Rubbing test

Take a pinch of cement in between the fingers and rub them. It should give a smooth feeling.

If it gives a gritty feeling, it means that the cement is not grounded to a particular degree of fineness or some setting might happen.

4.Hand insertion test

Thrust your hand into the cement bag and keep it for a minute. It must give you a cool feeling.

If you feel any considerable heat then it shows that the hydration reaction of cement has already taken and heat is liberated. This might affect the strength development.

5.Floating test

Take a handful of cement and throw it on a bucket with full of water. The cement particles should float for some time and then it should sink.

If they don’t sink after some time or if they sink immediately, it shows the possibility of adulteration in cement.

6.Strength test

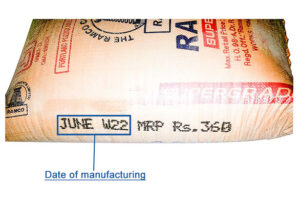

The date of manufacturing must be seen on the bag. It is the most important one because the strength of cement considerably reduces with age.

The cement should be used within three months from the manufacturing date.

The relationship between the period of storage and the strength of cement is listed below.

Period of storage | 28 day strength (in %) | Loss of strength (in %) |

Fresh | 100% | – |

3 months | 80% | 20% |

6 months | 70% | 30% |

12 months | 60% | 40% |

| 24 months | 50% | 50% |

If a sample of cement satisfies the above field tests it may be concluded that the cement is not bad and can be used for minor works. But it is always advisable to go for some preliminary lab tests.

Interesting facts and terminologies of cement

1) What is the setting and hardening of cement?

The setting describes the process of stiffening of cement paste. The plastic mass loses its plasticity and started to form a solid mass.

The term hardening indicates that the stiffened solid mass of concrete begins to attain useful and measurable strength.

2) What is the hydration of cement?

The chemical reaction that takes place between cement and water is called as Hydration of cement.

The cement hydration reaction is exothermic i.e., during hydration it liberates a considerable quantity of heat. This liberation of heat is called Heat of Hydration.

3) Who invented cement?

The invention of cement is attributed to Joseph Aspdin, a builder and bricklayer who in 1824 began his investigation by mixing hard ground limestone and finely divided clay into the form of slurry and calcined it in a furnace till CO2 was expelled. The mixture was then grounded to a fine powder. He called his cement as Portland cement and patented it on 21st October 1824.