What is the Bar Bending Schedule (BBS)?

A Bar Bending Schedule (BBS) is a document that provides the proper cutting length, bending length, and the total quantity of steel bars required for a particular construction.

It is presented in a tabular form for better understanding.

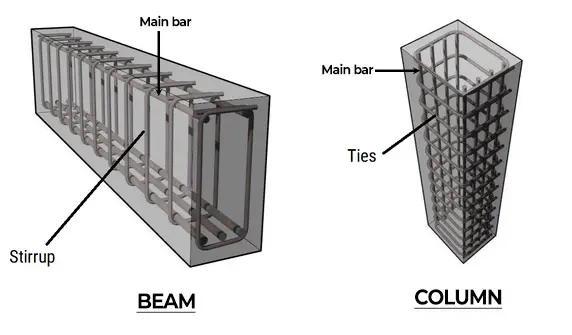

A bar bending schedule is prepared for each structural unit such as beam, column, slab, footing, etc.

BBS provides a significant role in preparing quantity estimations.

Here, we will discuss several important concepts and formulas that can be very useful while preparing/reading a bar bending schedule.

Why is a Bar Bending Schedule (BBS) needed?

Steel bars are used as a reinforcement in RCC structures to carry tensile forces.

While planning the construction, we may face several questions like,

- How much steel is required for my building?

- How much will be the cost?

- How much do I have to order? Etc…

The answer to all these questions lies in the bar bending schedule (BBS).

The BBS provides a clear understanding total quantity of bars required, the size of the bars, the cutting and bending length of the bars, the angle of bending, the number of bars for a member, the shape of the bars used, and the total cost of all the bars used, etc.

With the help of this accurate planning and scheduling, we can easily monitor the cost, quality, and safety of the structure.

Important concepts and formulas of Bar Bending Schedule (BBS)

A) Necessary Basics

- Unit weight (or) Density of steel = 7850 kg/m3.

- The standard length of the steel bar available at the market is 12m or 40ft.

- Weight of steel bar of 1m length = D2/162 kg, Where, D = Diameter of the bar.

Read more: How to find the weight of steel bars used in construction?

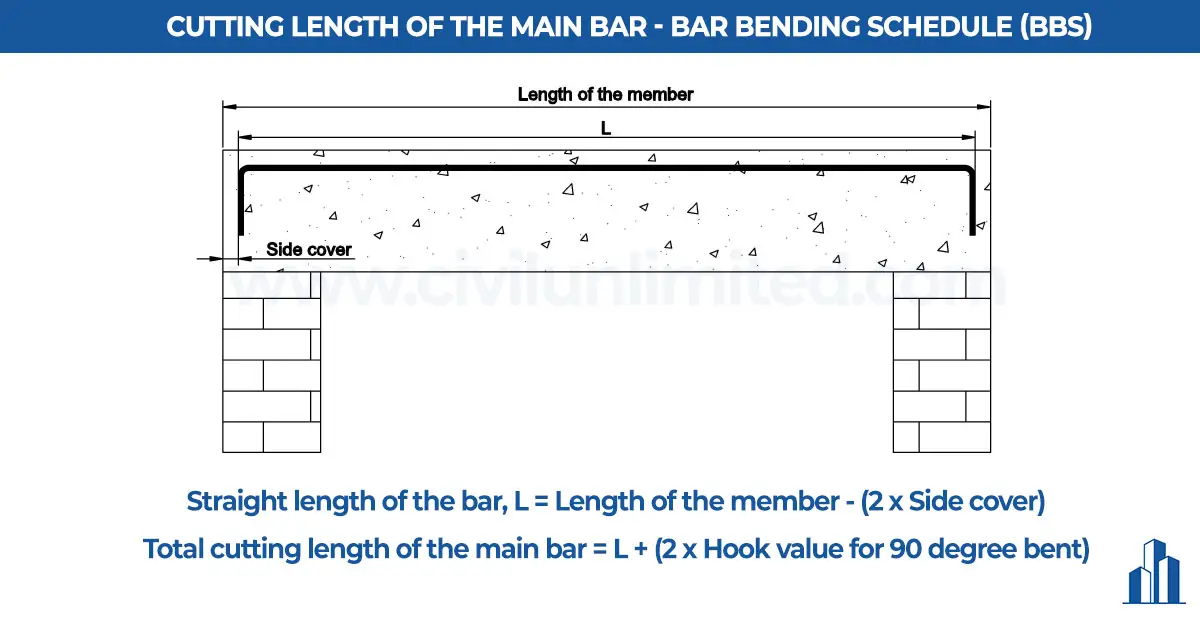

B) Cutting length of the main bar

The total length of the main bar depends upon the distance between the members and the hook length provided at the end of the member.

Total length of the main bar = Straight length + Hook length

i) Straight length of the bar

Length of straight bar = Total length – (2 x Side cover)

ii) Hook length of the bar

The hook length of the main bar refers to the length of the bar that is bent at the end to form a hook.

A hook is provided at the end to develop the anchorage between the steel and concrete.

- For a 180-degree bend, Hook length = 9D

- For a 90-degree bend, Hook length = 6D, Where D = Diameter of the bar.

Remember these are general values when HYSD bars are used. When you are using different types of bars such as Cold Twisted Deformed bars, these values may vary. Kindly refer to IS 2502: 1963 for more information.

However, in some cases, the hook length may be increased or decreased depending on the load distribution.

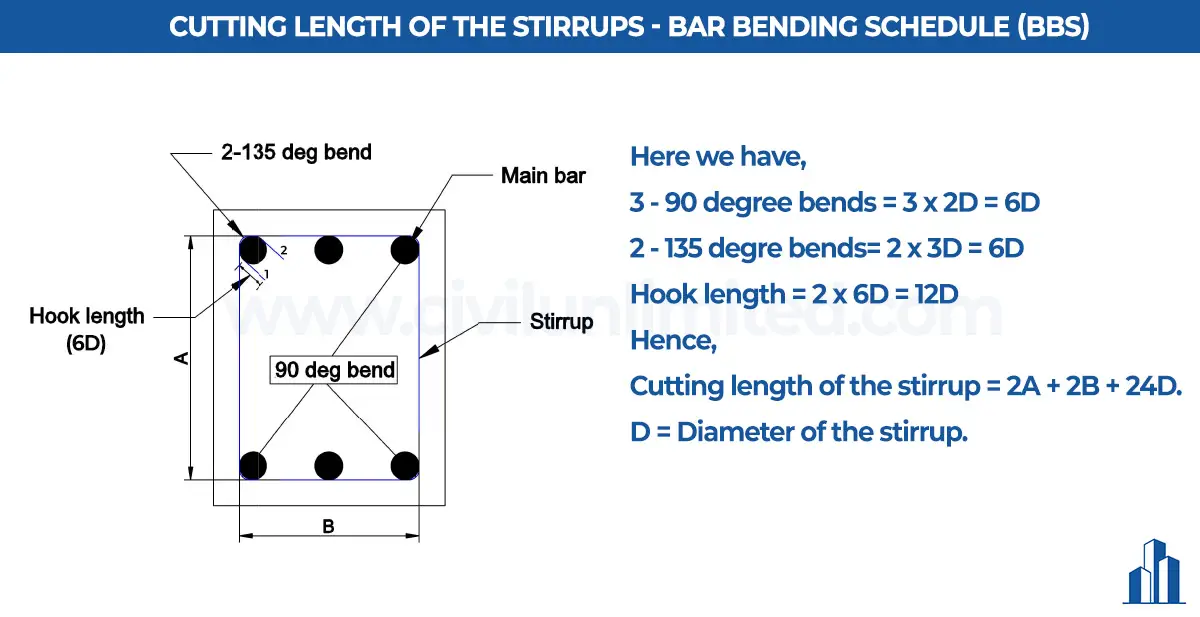

C) Cutting length of stirrup

The total cutting length of stirrups = Straight length + Bend length

The straight length of the stirrups depends upon the cross-section of the member.

Important values for calculating bend length are mentioned below,

- For 45-degree bend = Add 1D

- For 90-degree bend = Add 2D

- For 135-degree bend = Add 3D

The minimum hook length after the bend is 6D, Where D = Diameter of the bar.

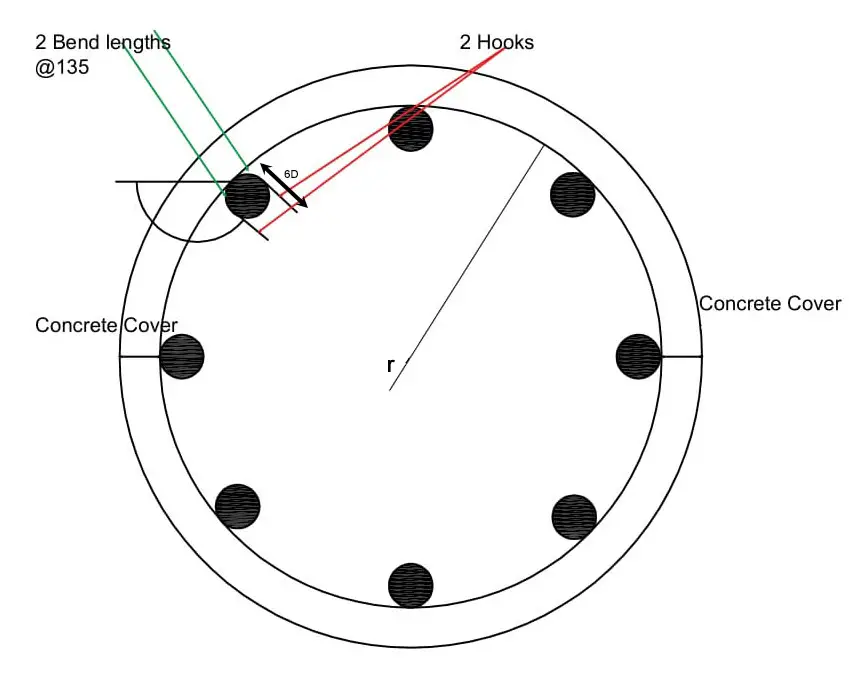

D) Cutting length of lateral ties

Cutting Length of the circular ties = Circumference of the tie + Hook value + Hook length

Circumference of the ties = 2 x pi x r,

r=D/2, D = Dia of the column – (2 x Clear cover).

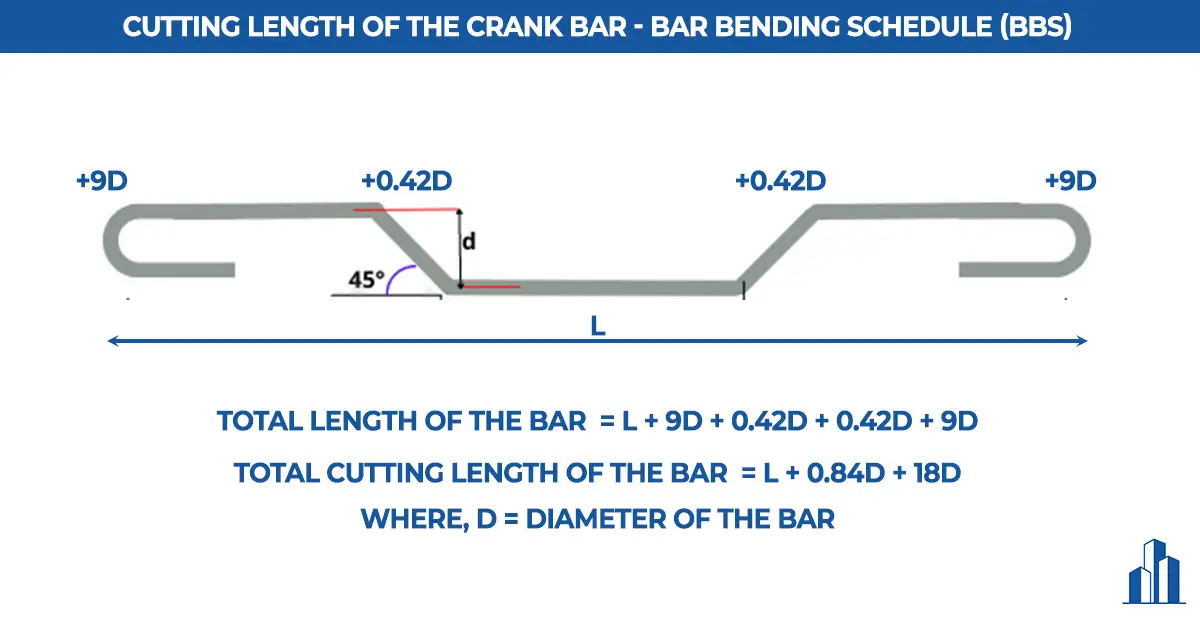

E) Cutting length of bent-up bar / cranked bar

Bent-up bar, also known as a Crank bar is used as the main reinforcement in a roof slab or in a double-reinforced beam.

The crank bars are usually provided near the end support of the slab/beam to resist the negative bending moment and shear force.

- For 30-degree crank = Add 0.27D

- For 40-degree crank = Add 0.42D

- For 60-degree crank = Add 0.58D

Refer to the picture below for a better understanding.

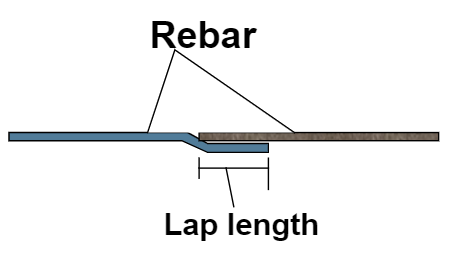

F) Lap length of the bar

Lap length is the minimum length that must be provided if two bars are joined together so that the forces can be transferred safely.

In general as a thumb rule, following lap lengths are adopted.

- For Columns – 45D to 50D

- For Beams – 60D

- For Slabs – 60D

Where D = Diameter of the bar.

If both the bars are of different dia, then the minimum dia should be taken as D.

Remember that the above values are used as a thumb rule, the data may vary according to the requirements and the force transfer.

Advantages of bar bending schedule (BBS)

1) BBS reduces the wastage of steel reinforcement in cutting by 5-10%.

2) When BBS is available, cutting and bending can be done at the factory and transported to the site which reduces the construction time.

3) It helps in improving the quality of the construction.

4) It provides a better estimation of the requirement of steel reinforcement for every structural member which can be used to compute the overall reinforcement requirement for the entire project.

5) It prevents the shortage of steel reinforcement for ongoing work by accurate estimation.

6) It also helps in procuring steel for the next phase of construction. And also prevents the stocking of extra steel reinforcement at the site for a longer time.

7) It becomes easy for site engineers to verify and approve the bending length and cutting length of steel reinforcement during inspection before concrete placement with the help of the bar bending schedule.

Format of Bar Bending Schedule (BBS)

| S.No | Bar Description | Bar Shape | No. of bar | Length of a bar (m) | Total length of a bar (m) | Dia of the bar (mm) | Unit weight of the bar (kg) | Total weight (kg) |

Bar Bending schedule software

There is a lot of software available to prepare or revise the bar bending schedules. Some of the important software are listed below.

- Microsoft Excel Spreadsheet

- MultiREBAR

- RGS REBAR

- RebarCAD

- Ensoft BarBeQue etc.

Hope you understand everything you need to know about the Bar Bending Schedule (BBS). If you find this article helpful (or) If you have any queries, let us know in the comment section.

Read more:

Let’s spread the love! Tag a friend who would appreciate this post as much as you did.

I just like the helpful information you provide in your articles