Have you ever been on a construction site or sitting in a lecture and heard people throw around terms like primary reinforcement, secondary reinforcement, stirrups, ties, chairs, and whatnot?

If your reaction was “What even are these?” then guess what? You’ve stumbled upon a perfect article. In this article, we are breaking down all those basic reinforcement terms and their details for you. So, buckle up!

Why reinforcement is provided in the concrete?

Concrete is a versatile material, used for various tasks within the construction industry. However, it is only able to withstand the compressive forces effectively. It cannot withstand the tensile forces.

In fact, the concrete’s ability to withstand tension is just about one-tenth of its capacity to withstand compressive forces.

To enhance the concrete’s ability to withstand tensile forces, it is necessary to introduce another material into the mix. This material needs to be capable of enduring high levels of tension, be flexible without breaking, and seamlessly blend with the concrete. Out of all the options, steel happens to be the most cost-effective choice that ticks all these boxes.

This is why steel is the go-to option for reinforcing various structural components like columns, beams, and slabs. The concrete which is reinforced with materials like steel is known as Reinforced Cement Concrete (RCC).

Column Reinforcement details

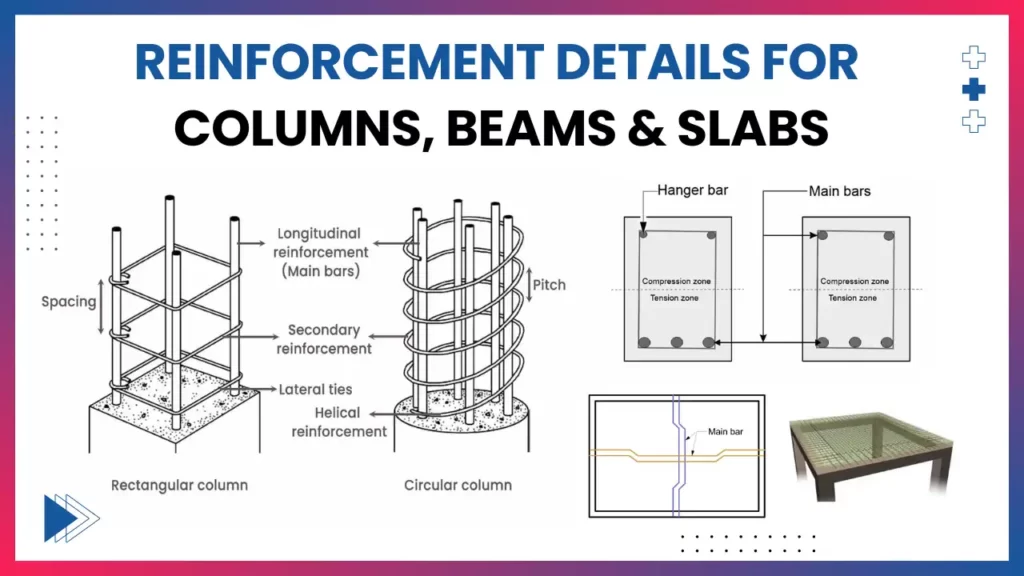

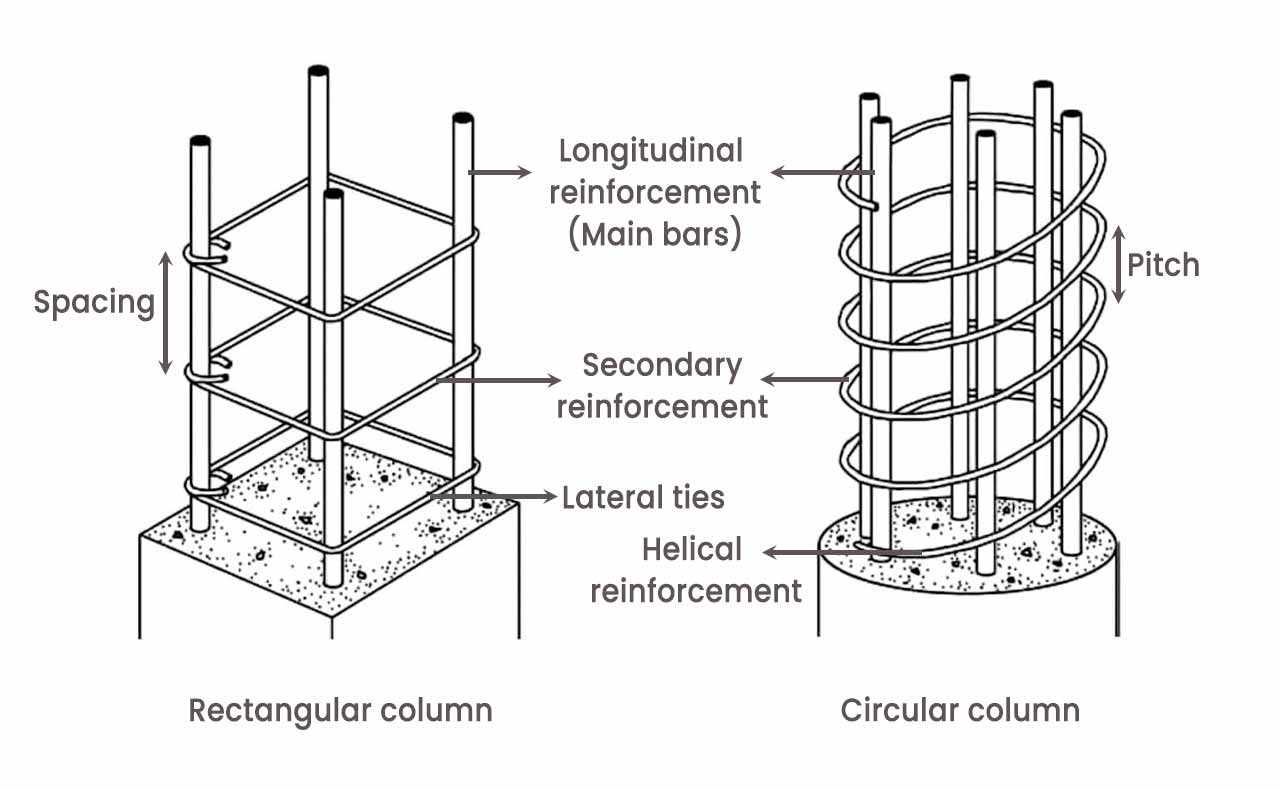

A column has two main types of reinforcement,

1) Primary reinforcement

In columns, it is also known as Longitudinal reinforcement or Main bar. The function of the main bars is to resist the axial compression load imposed on the column and to transfer it to the footing or the structure given below.

2) Secondary reinforcement

In a column, the secondary reinforcement is also known as Lateral ties. The Lateral ties are provided to keep the longitudinal bars in position and to provide lateral stability to the structure. Sometimes, instead of individual ties, a spiral bar should be provided known as Helical reinforcement.

Reinforcement Details & Provisions

The reinforcement details and provisions for RCC columns, according to IS 456:2000 are:

1. The maximum reinforcement for the column should not exceed 6% of the gross cross-sectional area of the column.

2. The Minimum reinforcement for the column should be at least 0.8% of the gross cross-sectional area of the column.

3. The minimum diameter of a bar that should be used as longitudinal reinforcement is 12mm.

4. The minimum diameter of a bar that should be used as secondary reinforcement (Lateral ties/Helical reinforcement) is 6mm.

5. The diameter of the lateral ties shall not be less than one-fourth of the diameter of the largest longitudinal bar.

6. The minimum number of longitudinal reinforcement bars for a rectangular column should be 4 (one for each corner).

7. The minimum number of longitudinal reinforcement bars for a circular column should be 6.

8. The spacing of lateral ties shall not be more than the minimum value among the following three:

- Least Lateral Dimensions (Minimum of breadth or Width)

- 16 x Diameter of smaller longitudinal reinforcement

- 300 mm

9. The spacing/pitch of helical reinforcement shall not be more than 75mm or one-sixth of the core diameter of the column. However, it shall not be less than 25mm or 3 times the diameter of the helical reinforcement.

10. A suitable clear cover should be provided in order to protect the reinforcement from environmental factors. A clear cover of at least 40 mm should be provided for columns.

Beam Reinforcement details

The different types of reinforcement used in the beam are,

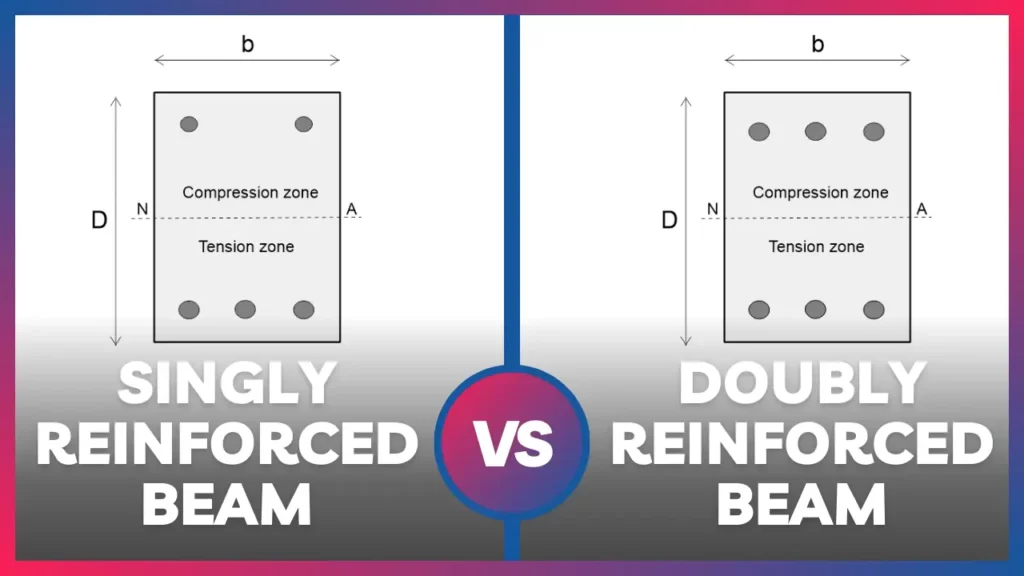

1) Primary reinforcement

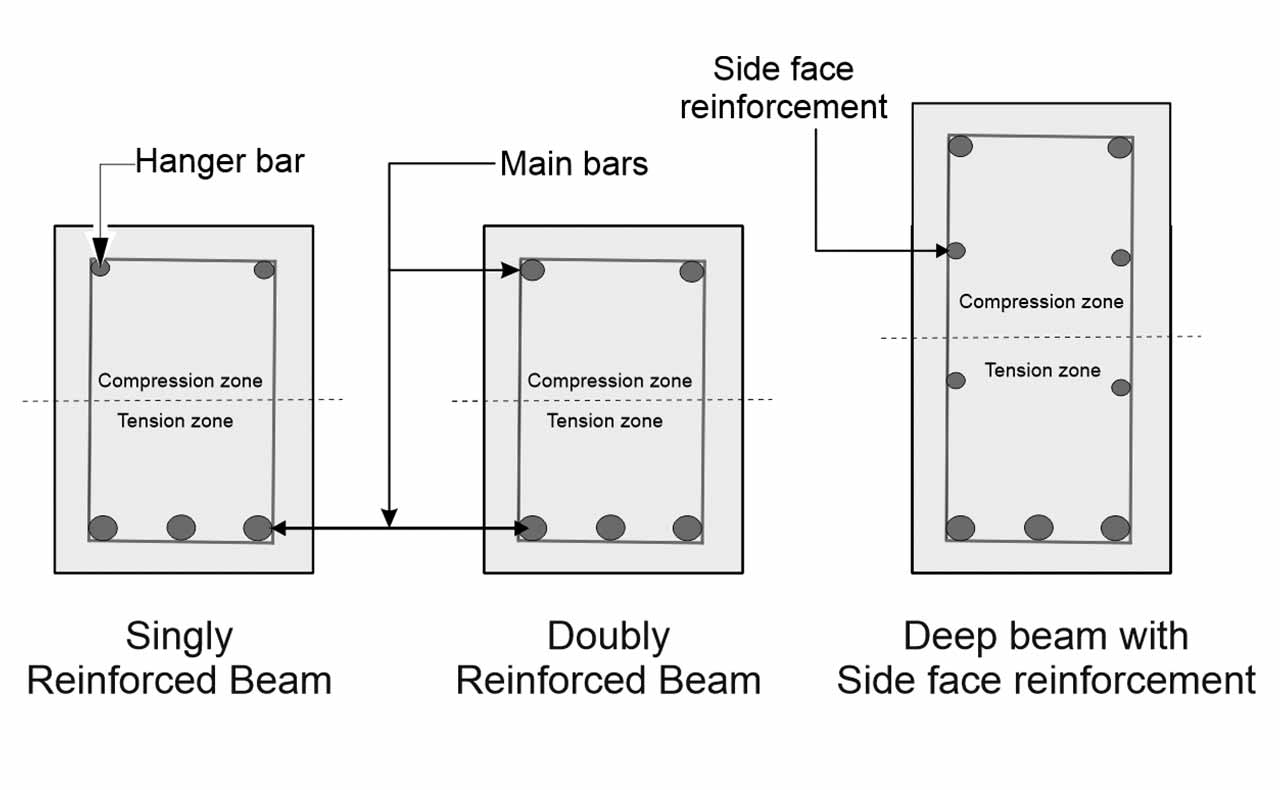

In beams, it is also known as Longitudinal reinforcement or Main bar.

- In singly reinforced beams, it is used to transfer and resist the tensile stress developed at the bottom of the beam due to bending.

- In doubly reinforced beams, the top main bar is used to transfer and resist excessive compressive stress produced in the beam, and the bottom main bar is used to transfer and resist the tensile stress produced in the beam.

Want to know what is the difference between a singly reinforced beam and a doubly reinforced beam?

Read this article: Difference between the Singly reinforced beam and Doubly reinforced beam

2) Secondary reinforcement

In beams, the secondary reinforcement is called as Shear reinforcement or stirrups. It is used to hold the main bars in position and to resist cracking, shrinkage, and temperature changes, thereby increasing the durability of the structure.

3) Hanger bar

In the singly reinforced beams, the main bar at the bottom is enough to carry the tensile stress produced in the beam. The compressive force produced in the beam is minimal and the concrete in the compression zone alone can be able to withstand it. However, we have to provide shear reinforcement to withstand the shear stress produced in the beam.

To keep the shear reinforcement in its position, we provide a minimum reinforcement at the compression (Top) zone. This is also known as Nominal reinforcement.

The bar provided in the compression zone of a singly reinforced beam is known as a hanger bar.

4) Side face Reinforcement

Side face reinforcement enhances lateral stability in deeper beams.

When the depth of the beam increases so much, the lateral rigidity of the beam decreases. To increase the lateral stability, a reinforcement is provided in the side face of the beam.

The side face reinforcement is provided under the following conditions:

- When the beam is not subjected to any torsional forces and the depth of the beam is greater than 750mm

- When the beam is subjected to any torsional forces and the depth of the beam is greater than 450mm

Reinforcement Details & Provisions

The reinforcement details and provisions for RCC beams, according to IS 456:2000 are:

1. The maximum reinforcement for the beam should not exceed 4% of the gross cross-sectional area of the beam.

2. The Minimum reinforcement for the beam should be calculated from the following formula: (Ast/bd) = (0.85/fy), where Ast = Area of steel reinforcement, b = width of the beam, d = effective depth of the beam, fy = grade of steel.

3. The maximum reinforcement for the hanger bar should not exceed 0.2% of the gross cross-sectional area of the beam and there is no limit to the minimum reinforcement.

4. The Minimum reinforcement for the side face reinforcement should be at least 0.1% of the gross cross-sectional area of the beam.

5. If all main reinforcement bars are of the same diameter, then the horizontal spacing between the main bars should be at least equal to the diameter of the bar.

6. If the main reinforcement bars are of varying diameter, then the horizontal spacing between the main bars should be equal to the diameter of the larger bar.

7. In any case, the horizontal spacing between the main bar shall be 5mm more than the nominal size of aggregates, so that the aggregate may pass through it while pouring concrete.

8. The maximum spacing for shear reinforcement shall be

- 0.75D for Vertical stirrups (D = Diameter of the bar)

- D for Inclined stirrups. However, In both cases, the spacing shall not exceed 300mm

9. A suitable clear cover should be provided in order to protect the reinforcement from environmental factors. A clear cover of at least 25 mm should be provided for beams.

Slab Reinforcement details

The different types of reinforcement used in the slab are,

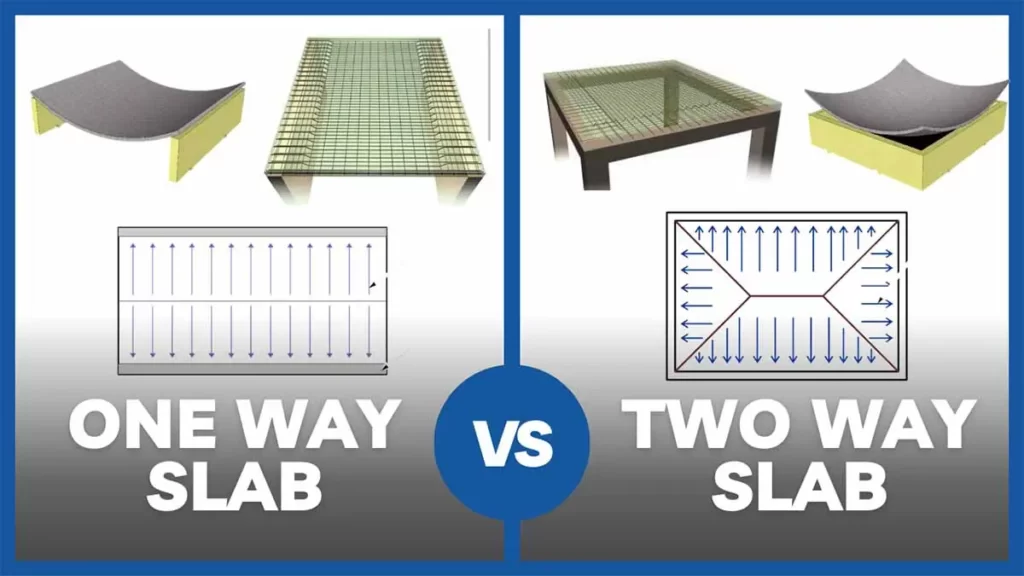

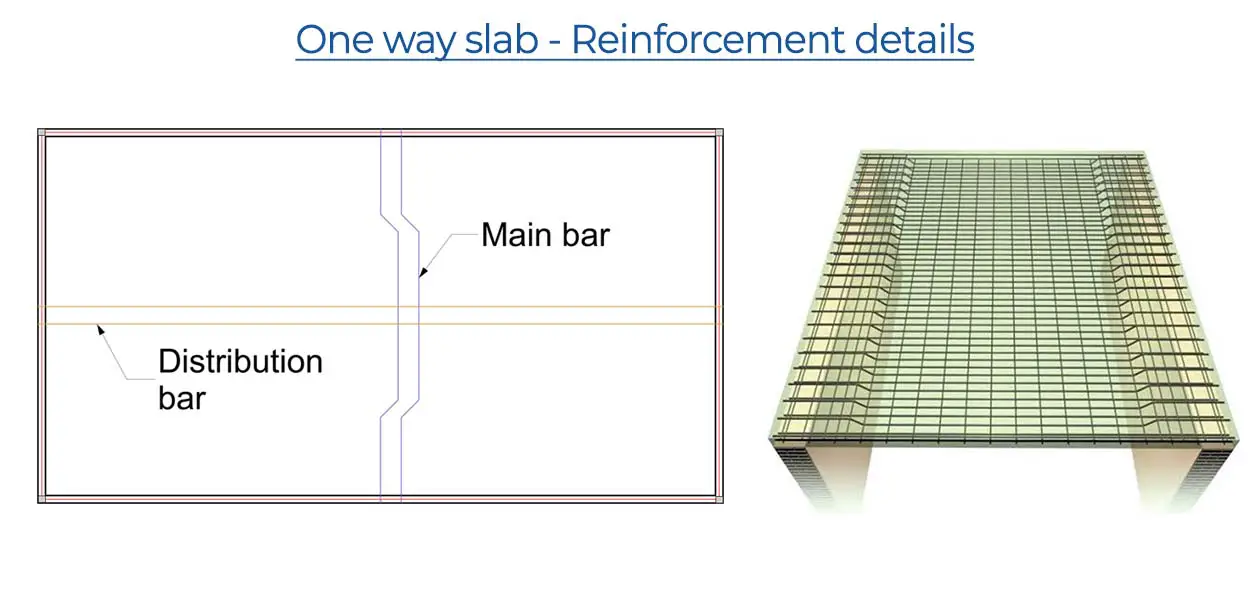

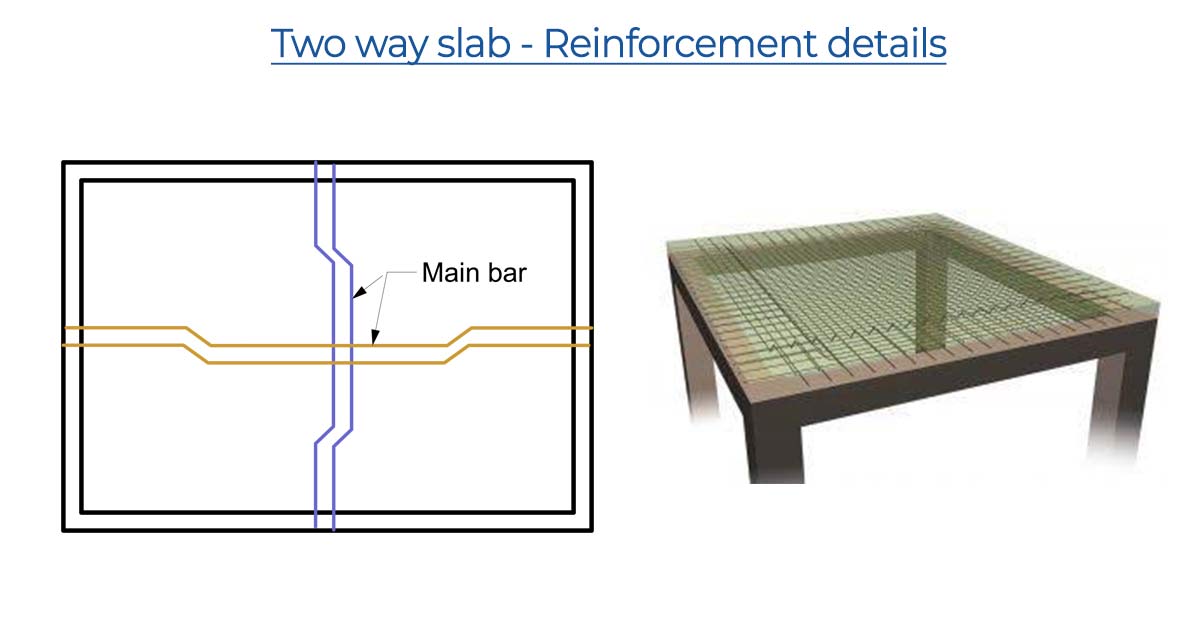

1) Primary reinforcement

In slabs, it is also known as Main bars. It is used to transfer the bending moment developed at the bottom of the slab to the beam.

- It is placed along a shorter span direction in a one-way slab

- It is placed along both the directions in a two-way slab

Want to find out why?

Read this article: 10 Difference between One way slab and Two way slab

2) Secondary reinforcement

In slabs, the secondary reinforcement is called as Distribution reinforcement. It is used to resist cracking, shrinkage, and temperature changes, thereby increasing the durability of the structure.

3) Chair bar

Chair bars are used to maintain the proper vertical position of the reinforcement bars within the slab. They ensure that both the top and bottom bars are at the correct depth from the surface of the slab.

Reinforcement Details & Provisions

The reinforcement details and provisions for RCC slabs, according to IS 456:2000 are:

1. The maximum diameter in the slab shall not be greater than one-eight of the thickness of the slab.

2. The Minimum reinforcement for the slab should be

- 0.15% of the gross cross-sectional area of the slab, in the case of using mild-steel reinforcement.

- 0.12% of the gross cross-sectional area of the slab, in the case of using HYSD bars.

3. The maximum spacing for main reinforcement shall be 3D or 300mm, whichever is smaller. (D=Diameter of the bar)

4. The maximum spacing for secondary reinforcement shall be 5D or 300mm, whichever is smaller. (D=Diameter of the bar)

5. A minimum clear cover of 20mm should be provided for slabs.

Hope you understand everything you need to know about the reinforcement details of columns, beams, and slabs. If you found this article helpful, let us know in the comment section.

Read more:

Bar Bending Schedule (BBS) – Important Concepts and Formulas