What is shotcrete?

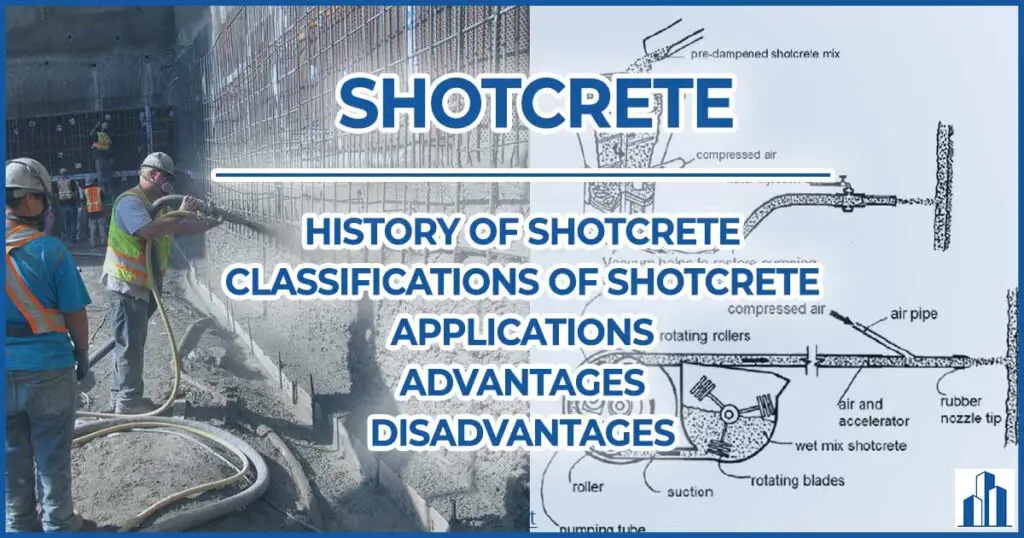

A shotcrete is a method of applying concrete through a nozzle at a high velocity onto a surface that is already strengthened with reinforcement or steel wire mesh.

The impact created by the application process consolidates the concrete. This innovative technology was invented to make the concreting work faster and more immediate.

History of shotcrete

This technology was originally invented in 1907 by an American taxidermist called Carl Akeley. He used the dry mix process, i.e a method of blowing out dry cement & aggregate mix, out of the hose with compressed air, injecting water at the nozzle as it was sprayed. (we’ll discuss this in detail below).

In 1911, he patented his invention in the name of gunite since the concrete mixture is applied from a pneumatic gun (gun-ite).

The dry mix process was used until a new method called the wet mix process was invented in the 1950s.

Difference between Shotcrete and Gunite | Shotcrete Vs Gunite

Gunite was originally the trademark coined by Carl Akeley and referred to the dry-mix pneumatic cement application process.

The term shotcrete was first defined by the American Railway Engineers Association (AREA) in the early 1930s. Shotcrete is an all-inclusive term that is used to refer to the spraying concrete that is either prepared by dry-mix or wet-mix process.

However, people incorrectly used the term shotcrete to distinguish the wet-mix method from the dry-mix method. For example, In pool construction, people conventionally used the term shotcrete to refer to the wet mix method and Gunite to refer to the dry mix method, which is totally wrong.

Ingredients of shotcrete

The hardened properties of shotcrete are similar to those of conventional cast-in-place concrete, the only difference is the application process. Hence, the ingredients are also the same as that of conventional concrete. The ingredients of shotcrete are,

- Cement

- Fine aggregate

- Coarse aggregate (below 10mm size)

- Water and

- Admixtures

The size of the aggregate plays a vital role in the pumping process. For,

- Shotcrete mortar (size below 2.5 mm)

- Shotcrete concrete (Size below 10mm)

- Sprayed concrete (or) Syring concrete (Size below 25mm)

Classification of shotcrete technology

Classified based on two processes namely,

- Dry mix method

- Wet mix method

1) Dry mix method

The dry ingredients of the shotcrete are fed into the hopper. The ingredients are slightly damped so that the dust produced while spraying will be minimum. With the help of compressed air, the dry ingredients are fed into the pneumatic hose and exit the hose via a nozzle.

Water is stored in a separate container and added to the mix at the nozzle. The nozzleman can control the addition of water at the nozzle. So, this process requires a skilled nozzleman.

Advantages of the dry mix method

1) The water content can be adjusted instantaneously by the nozzleman, allowing more effective placement in overhead and vertical applications without using accelerators.

2) It is very useful in repair works that have the need to stop frequently. The ingredients can be drained & cleaned from the hose very easily.

Disadvantages of the dry mix method

The dust produced while the ingredients are sprayed from the nozzle can be very high sometimes. This can waste some ingredients and is not efficient when the shotcrete quantity is high.

2) Wet mix method

In this process, all the ingredients of concrete including water are mixed separately in an individual container and pumped into the hose. The compressed air is delivered into the hose near the nozzle to impel the mixture to the surface.

Advantages of the wet mix method

1) Less dust compared to the dry mix method

2) Produce less waste (material falls to the ground)

3) Larger volumes can be placed in less time than the dry process.

Disadvantages of the wet mix method

The mixing process should be monitored carefully and the cleaning process is slightly more difficult than the dry mix method.

Applications of shotcrete

1. Used in the rehabilitation of subway tunnels.

2. Used in the construction of domes.

3. Can be widely used in curved or folded sections.

4. Most widely used in the construction of swimming pools and water retaining structures etc.

5. Used to prepare precast members.

6. Used to construct retaining walls and also utilized in the stabilization of slopes.

7. Used to provide refractory lining of kilns, chimneys, furnaces, etc.

Advantages of shotcrete technology

1. Since the shotcrete is expelled by the nozzle at high pressure, it undergoes placement and compaction at the same time.

2. Shotcrete is dense, strong, more homogeneous, and acts as waterproof material. Shotcrete is generally stronger than cast-in-place concrete.

3. The application of shotcrete is very simple. It can be impacted onto any type of shape of the surface, including vertical or overhead areas.

4. It can be used on a surface that is having less reinforcement than the amount which is required for conventional concrete.

5. The shotcrete technology allows us to modify the water-cement ratio whenever required.

6. It also minimizes manpower.

7. It also minimizes the quantity of formwork needed.

Disadvantages of shotcrete technology

1. The procedure is more complicated than the conventional concrete, hence highly skilled persons are needed to perform the work.

2. The wastage of concrete is somewhat higher if shotcrete is performed over any vertical (or) overhead surfaces.

3. Amount of time required to finish the work is a little higher when compared to the conventional process.

4. Production cost is higher.

Hope you understand everything you need to know about the shotcrete technology. If you have any queries (or) if you find this article helpful, let us know in the comment section.

Read more: Plane Table Surveying – Instruments, Setting up, Advantages & Disadvantages, How to calculate the quantity of cement and sand required for plastering?.