What is the Crazing of concrete?

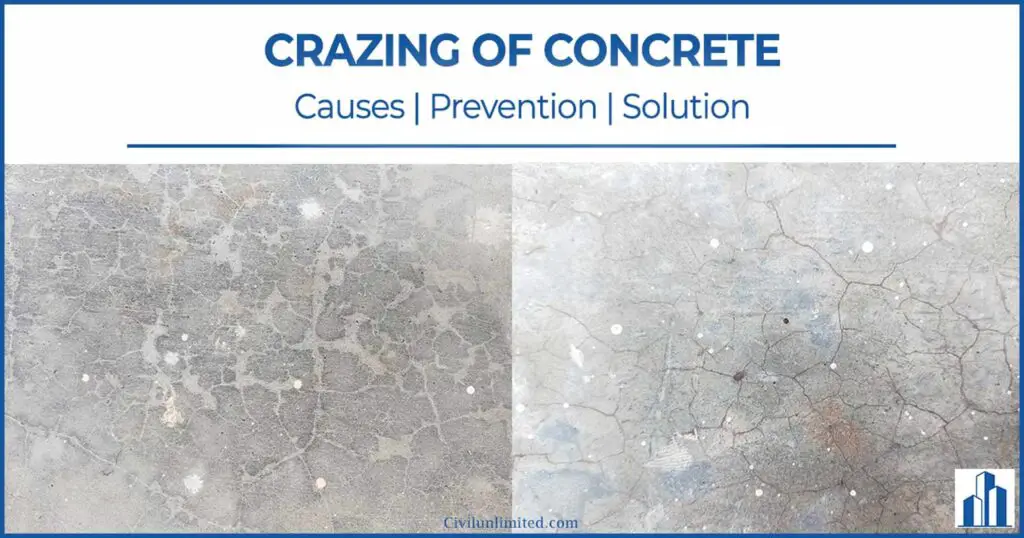

Crazing is the development of a network of fine random cracks on the surface of the concrete caused by shrinkage of the surface layer.

These cracks are very fine (3 mm) and they do not penetrate much below the concrete surface.

These cracks often look like a spider web (or) resemble a pattern of irregular hexagons. So, these cracks are also called Map cracks or Pattern cracks.

Is concrete crazing bad?

These crazing cracks are superficial. They are rarely deeper than one-eight of an inch. So they do not affect the structural integrity of concrete and rarely affect the durability of the structure.

These cracks are not always readily visible until the surface has been wetted and begins to dry out.

Even though it is not a structural concern but the crazed surfaces can be unsightly and absolutely no one wants to degrade the look of their building because of the crazed concrete floor.

So let’s see what are the reasons for crazing and prevention methods and the solution for crazed concrete surfaces.

What causes crazing cracks in concrete?

1) Climatic conditions – When the temperature is high and the sun is shining with high winds and low humidity, the surface of the concrete tends to dry faster which encourages crazing cracks on concrete.

2) Poor or inadequate curing – The delayed application of the curing and even the alternate wetting and drying of the concrete surface at early age results in concrete crazing.

It would be essential to note that the water used for curing shall not be more than 11°C (20°F) cooler than the concrete temperature.

3) Excessive troweling of the concrete surface brings cement slurry to the top and produces a skin layer, which is susceptible to higher shrinkage than the underlying concrete.

4) Sprinkling dry cement on the top surface to dry up the bleeding water to hasten the finishing process is the most frequent cause of crazing cracks. This sprinkling action concentrates the fines on the top surface which is more susceptible to drying shrinkage.

5) Overuse of vibrating screeds can cause the aggregates to settle down and the cement slurry to settle on top which in turn causes crazing cracks.

6) Sometimes the crazing may cause due to too much clay or dust in the aggregates used.

How to prevent the crazing cracks in concrete?

1) Schedule the concrete placement at night (or) on an overcast day to reduce the risk of rapid temperature or moisture change in the concrete surface.

2) To prevent crazing, curing procedures should begin early within minutes after the finishing process.

3) keep the concrete surface wet either by flooding it with water or covering it with a jute bag for a minimum of 3 days.

The three days mentioned here are just the minimum criteria, the optimum curing period varies according to the types of cement.

4) NEVER EVER sprinkle dry cement on the concrete surface to absorb bleed water or to facilitate easy finishing. Please wait some time for the bleed water to dry out and then carry out the finishing process.

5) Avoid over-troweling the finished surfaces.

6) Avoid the high temperate difference between the concrete and the curing water.

7) Use moderate slump concrete to produce the concrete of the required strength without causing any bleeding or segregation.

8) Avoid over-vibrating the concrete during placement.

Wonder how to check the quality of cement before using it at the site. Read here.

Can you fix concrete crazing?

As stated above, the crazing of concrete is not much of a structural concern. It only affects the aesthetics.

The only economical solution to improve aesthetics is to cover the crazing surface with epoxy coatings.

During the preparation work, the top surface was almost grounded to facilitate epoxy bonding, it minimizes the crazing and makes it less noticeable. In addition to that, with epoxy coating, you can choose a color, pattern, or texture that will completely eliminate any remaining crazing from the view.

For more guidelines, follow GUIDE TO CONCRETE FLOOR AND SLAB CONSTRUCTION (ACI 302. 1 R-15).

Quick checklist

So, here is a quick checklist to remember the important points before, during, and after concrete placement.

1) Before concrete placement

- Choose a less temperature day for concreting.

- Check the mix design for the concrete slump.

- Prepare the necessary accessories for curing.

2) During concrete placement

- Make sure to wet the subgrade before concrete placement to prevent moisture absorption from the concrete.

- Avoid over vibration of concrete.

- Avoid finishing the surface with bleed water.

- Avoid sprinkling cement to dry out the bleeding water.

- Avoid over-troweling the finished surface.

3) After concrete placement

- Begin early curing procedures.

- Check the water temperature. The water used for curing shall not be more than 11°C (20°F) cooler than the concrete temperature.

- Avoid alternate wetting & drying of concrete surface.

- Keep the curing for the minimum number of days.

Hope you understand everything you need to know about the crazing of concrete. If you have any queries (or) if you find this article helpful, let us know in the comment section.

Read more: An Ultimate Guide For Mixing Of Concrete, Gradation of Aggregates and its importance.