Before learning about the rebound hammer test and its procedure, let’s learn what is Non Destructive Test of concrete.

What is the Non-Destructive Test of concrete?

Non Destructive Test (NDT) is a method of evaluating the parameters like strength & durability of existing concrete structures without causing any damage to the structure.

The standard method for evaluating the quality of concrete in structures is to cast a cylinder (or) cube specimen and test it in particular intervals.

The main disadvantage of this method is these specimens may not reflect the real-time strength of the structures because of varying parameters like different curing conditions & compaction methods etc. To overcome these difficulties NDT tests are carried out.

Non-destructive tests of concrete can be used for the following purposes,

- Test on actual structures

- Test on several locations

- Assess the quality control of actual structures

- Asses the uniformity of the concrete

- Asses the extension of cracks & voids

- Assess the workmanship & poor construction practices

Among the several methods of NDT, the Rebound hammer is the most common and widely used test.

What is the Rebound hammer?

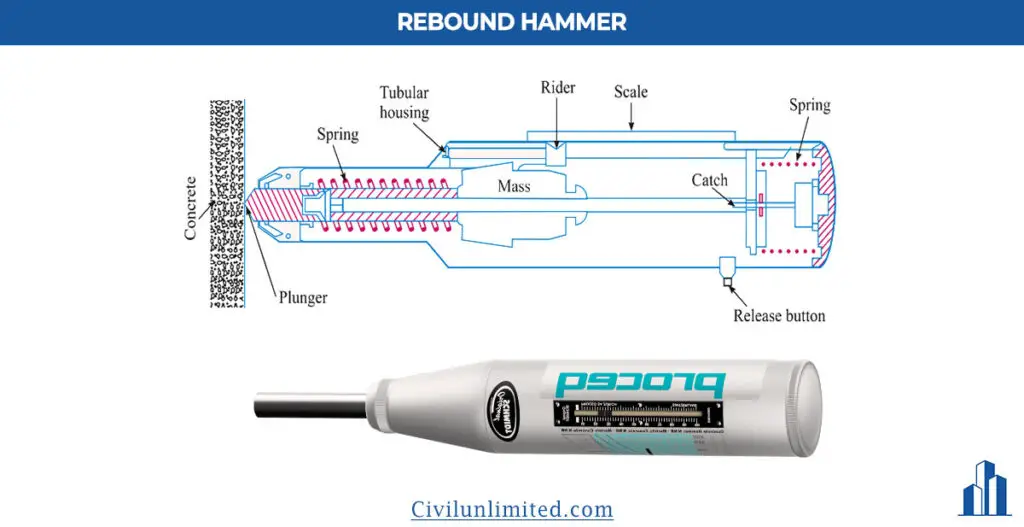

Rebound hammer (or) Schmidt’s Rebound Hammer is an instrument that consists of a spring control hammer that slides on a plunger within a tubular housing. It is commonly used for measuring the surface hardness of concrete.

The rebound hammer could be used for,

- Assessing the compressive strength of the concrete with the help of a suitable relationship between the rebound number and compressive strength.

- Assessing the uniformity and quality of concrete,

- Assessing the quality of one element of concrete to another with respect to standard requirements.

There are several types of hammers with varying impact energy from 0.07 Kgm to 3 Kgm. The high-impact energy hammers are used for mass concrete, road pavements & airport runways. The low-impact energy hammers are used for low-strength materials.

Principle of Rebound hammer test

When the plunger of the rebound hammer is pressed against the surface of the concrete, the spring-controlled mass rebounds, and the extent of such rebound depends upon the surface hardness of the concrete.

The rebound is read off from the graduated scale and designated as a Rebound number (or) Rebound Index.

Then the rebound number is related to the compressive strength of the concrete by a standard relevant graph.

How Rebound hammer works?

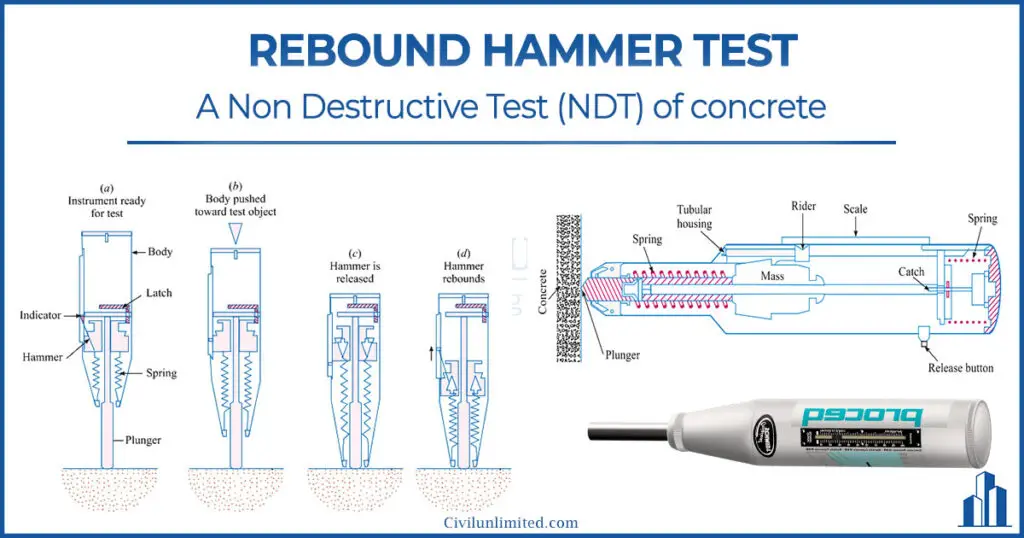

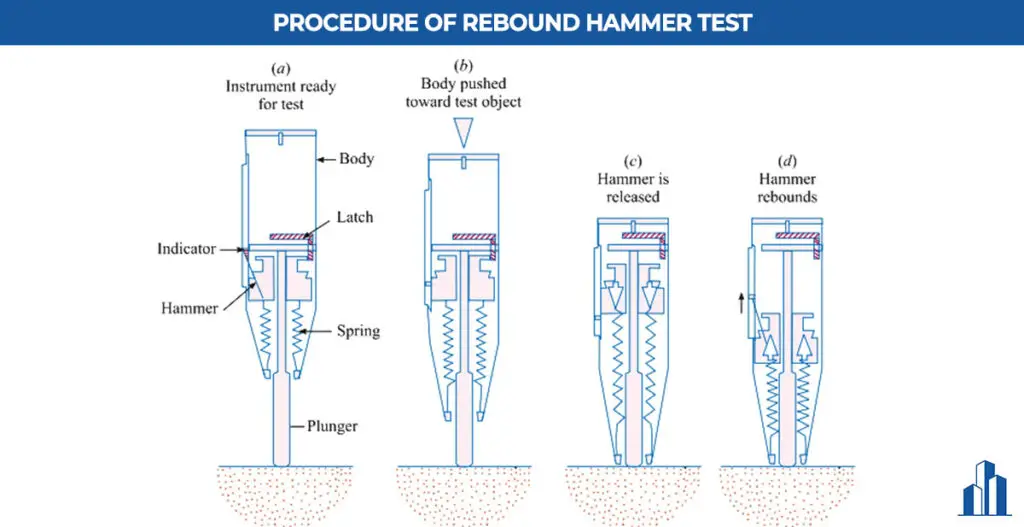

The rebound hammer consists of a spring control hammer that slides on a plunger within a tubular housing.

When the instrument body (tubular housing) is pushed toward the concrete specimen, the plunger is pressed against the surface of the concrete. The mass attached to the plunger will go up until it reaches the top. Once, it reaches the top, the hammer is released.

The mass impacts against the spring system that is attached to the plunger. The mass rebounds, taking the rider with it along the guide scale. The distance travelled by the rebounded mass is called the rebound number. It is indicated by the rider moving along a graduated scale.

Procedure for Rebound hammer test

1) For testing, the smooth, clean and dry surface should be selected. If there are any scaling or loose particles on the concrete structure, they should be removed.

2) The point of testing should be at least 20 mm away from any edge or shape discontinuity.

3) While performing the procedure, the rebound hammer should be at the right angle to the concrete surface.

4) A minimum of 6 readings should be taken at each point of observation. The average of these readings becomes the rebound hammer number for that point of observation

However, it is important that each reading should not differ by more than 7 units. If more than two readings differ from the average of 7 units, then the entire set of readings should be taken afresh.

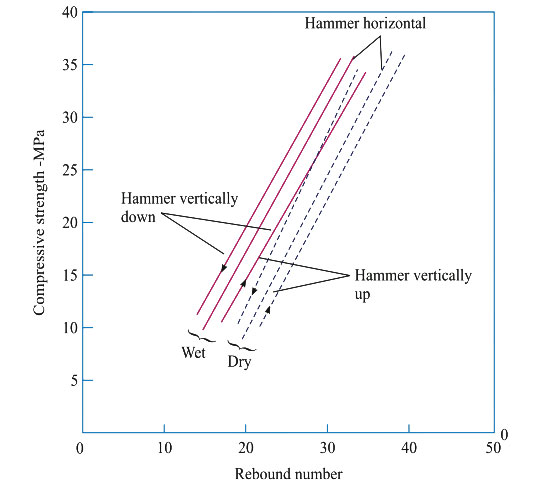

The estimation of concrete compressive strength from rebound number is determined from a standard calibration curve based on laboratory results.

The test also can be conducted horizontally, vertically—upwards or onwards, or at any intermediate angle. At each angle, the rebound number will be different for the same concrete and will require separate calibration or correction chart.

Procedure of obtaining the relation Between Compressive Strength and Rebound Number

One way to obtain the relation between the compressive strength and rebound number is to measure both properties simultaneously on the concrete cubes.

The test specimens should be as large a mass as possible in order to minimize the size effect on the test result.

150 mm cube specimens are preferred for calibrating rebound hammers of lower impact energy (2.2 Nm), whereas for rebound hammers of higher impact energy, for example, 30 Nm, the test cubes should not be smaller than 300 mm.

At least nine readings should be taken on each of the two vertical faces of the specimen. The points of impact on the specimen must not be nearer an edge than 20 mm and should be not less than 20 mm from each other. The same points must not be impacted more than once.

Then the concrete cube specimens are held in the compressive testing machine and the compressive strength of the concrete is tested as per IS 516: 1959.

Then these values are plotted in the graph to serve as a calibration chart. In cases where these procedures are not possible to perform, we can use typical calibration charts.

Influence on test conditions

The rebound numbers are influenced by several factors like,

1) Type of cement

Concretes made with high alumina cement can give strengths 100 percent higher than that of ordinary Portland cement.

Concretes made with super sulphated cement can give 50 percent lower strength than that of ordinary Portland cement.

2) Type of aggregate

Different types of aggregate used in concrete give different correlations between compressive strength and rebound numbers.

Normal aggregates such as gravel and crushed rock aggregates give similar correlations, but concrete made with lightweight aggregates requires special calibration.

3) Amount of compaction

All correlations assume full compaction, as the strength of partially compacted concrete bears no unique relationship to the rebound numbers.

4) Surface condition

Trowelled and floated surfaces are harder than moulded surfaces and tend to overestimate the strength of concrete.

5) Surface moisture content

A wet surface will give rise to an underestimation of the strength of concrete. The results can give 20% lower strength than in an equivalent dry concrete.

6) Influence of curing

Variations in curing conditions and in exposure can influence the relationship. Separate calibration curves are required for different curing regimes.

7) Age of concrete

The effect of age can generally be ignored for concrete between 3 days and 3 months old.

8) Influence of carbonation on concrete surfaces

The influence of carbonation of concrete surface on the rebound number is very significant. Carbonated concrete gives an overestimate of strength which in extreme cases can be up to 50 percent.

Interpretation of results

The rebound hammer method provides a convenient and rapid indication of the compressive strength of concrete by means of establishing a suitable correlation between the rebound index and the compressive strength of concrete.

The following table shows the quality of concrete from the rebound number.

| Average rebound number | Quality of concrete |

| Greater than 40 | Very good hard layer |

| 30 to 40 | Good layer |

| 20 to 30 | Fair |

| Less than 20 | Poor concrete |

| 0 | Delaminated |

It should be noted that the rebound values reflect the concrete quality up to a depth of 50mm.

The estimation of the strength of concrete by the rebound hammer method cannot be held to be very accurate and the probable accuracy of prediction of concrete strength in a structure is ±25 percent.

Advantages of Rebound hammer test

1) We can check the uniformity of the concrete

2) Approximate estimation of strength by using laboratory-calibrated graphs

3) The apparatus is easy to use and inexpensive

4) Used to assess the quality of the concrete structure.

Disadvantages of Rebound hammer test

1) The device needs regular calibration.

2) Only we can able to assess the quality of concrete to a limited depth.

3) Flaws like the presence of cracks and voids cannot be detected.

4) The test results can be affected by several parameters like surface condition, moisture content, etc.

If you want to know more about the test, refer to IS 13311: 1992 Part 2.

Hope you understand everything you need to know about the Rebound hammer test. If you have any queries (or) if you find this article helpful, let us know in the comment section.

Read more: Bulking of Sand & its significance, Mivan shuttering – Everything you should know.