Concrete is a composite material that is mainly made up of cement, aggregates, and water.

To yield good quality concrete, one must know about the ingredients that make up the concrete.

Without the study of the aggregates, the study of the concrete is incomplete. So let’s understand the properties and classification of the aggregates.

Aggregates

The aggregates are the natural or artificial mineral materials that are used in the manufacturing of concrete. It is an important constituent of concrete that almost occupies approximately 65- 70% of the total volume.

According to IS 383-1970, a good aggregate for concrete construction should be chemically inert, strong, hard, and durable.

Why are we using aggregates in the concrete?

- Usually, the aggregates are used as a filler material in the concrete to replace a minimum quantity of cement which reduces the cost of concrete production. Because the price of cement is way more higher than the aggregates.

- Aggregates can reduce the shrinkage caused by the cement thereby reducing shrinkage cracks and improving the durability of the concrete. About a 10% reduction in aggregate volume can double the shrinkage.

- Aggregates impart unit weight to the concrete thereby making the body of the concrete.

Classification of Aggregates

The aggregates can be widely classified according to their,

- Method of formation

- Source of formation

- Unit weight

- Size and

- Shape

Let’s study the properties of aggregates in each classification,

1) Method of formation

Based on the method of formation, aggregates can be classified as Natural aggregates and artificial aggregates.

Natural aggregates such as sand, gravel, and crushed rock such as granite, quartz, and sandstone are used for manufacturing reinforced concrete.

Artificial Aggregates such as furnace clinker, broken brick, and air-cooled slag are used for manufacturing concrete of low density.

2) Source of formation

All natural aggregates are originated from a bedrock. Based on their mode of formation, there are three kinds of rock namely, Igneous rock, Sedimentary rock, and Metamorphic rock.

a) Aggregates from Igneous rock

These rocks are formed by the cooling of molten magma on or inside the earth’s surface during a volcanic eruption.

The aggregates made from igneous rocks are normally strong, hard, tough, and dense. The aggregates may be light or dark-coloured. But the aggregates formed from the igneous rock may be chemically active and may react with the alkalies present in the cement. Hence due importance should be given.

Examples of aggregates from igneous rock are,

- Granite

- Basalt

- Trap etc.

b) Aggregates from Sedimentary rock

These rocks are formed by the deposition of weathering products on the pre-existing rock. The weathering process may be caused by sun, rain, and wind.

When the deposition happens in the ocean bed, the material gets subjected to the static pressure of water and gets compacted tightly.

Sedimentary rocks vary from soft to hard, porous to dense, and light to heavy based on their degree of consolidation.

Examples of aggregates from sedimentary rock are,

- Sandstone

- Limestone

- Gravel etc.

C) Aggregates from Metamorphic rock

When Igneous or sedimentary rock gets subjected to high heat and pressure, it causes metamorphism in the rock which results in the change of texture and structure of rocks.

Metamorphic rock shows a foliated structure which often considered as an undesirable character of an aggregate. But it definitely depends upon the depth of the foliation.

Examples of aggregates from sedimentary rock are,

- Quartzite

- Gneiss etc.

3) Unit weight of an aggregate

According to their unit weights, aggregates are classified as below.

a) Normal Weight Aggregate (NWA)

These are the commonly used aggregates such as sand, gravels, granite, and sandstone which have specific gravities between 2.5 and 2.7 and produce concrete of unit weight ranging from 23 to 26 KN/m3.

b) Light Weight Aggregate (LWA)

The Light weight aggregates are having unit weight up to 12KN/m3 and are used to manufacture light weight concrete and structural bricks for reducing the self-weight of the structure.

c) Heavy Weight Aggregate (HWA)

These aggregates are having a unit weight of about 28 to 29 KN/m3 and are used in the manufacturing of heavy weight concrete which is used as a shield against radioactive radiation.

4) Size of aggregates

The aggregates according to their sizes classified as follows.

The materials having particle size less than 2 microns (0.002 mm) are called as Clays.

The materials having particle size varying from 0.002 to 0.06 mm is termed as Silt.

These clay and silt materials are almost like dust materials and their presence is harmful to the durability of the concrete. Hence these are also known as deleterious substances. The quantity of deleterious substances should be less than 5% of the weight of aggregates.

The materials which pass through a 4.75 mm IS sieve and entirely retain on a 75-micron sieve are called fine aggregates. It may be natural river sand, crushed stone sand, or crushed gravel sand.

The materials which pass through a 75 mm IS sieve and entirely retain on a 4.75 mm sieve are called coarse aggregates. It may be crushed gravel or stone.

If the size of the aggregate is more than 75 mm, then it is called cyclopean aggregate.

If the aggregates consist of all the fractions of fine and coarse aggregate, then it is called all-in-aggregate.

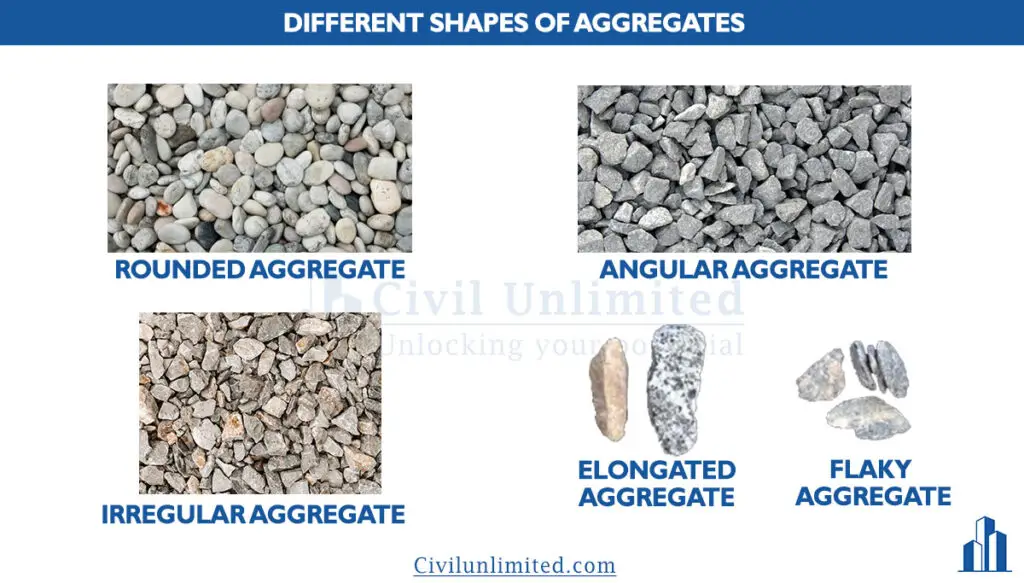

5) Shape of aggregates

The shape of aggregates is an important characteristic since it affects the workability of concrete. The aggregates according to their shape, are classified as follows,

- Rounded aggregates

- irregular aggregates

- Angular aggregates

- Flaky aggregates and

- Elongated aggregates.

a) Rounded aggregate

These aggregates are fully water-worn or completely shaped by attrition. River gravels and seashore gravels are the best examples of rounded aggregate.

When the rounded aggregates are filled in the container, due to the smooth surface and less friction in-between them, the aggregates slides to each other and compact naturally. Thus, it will have the minimum voids ranging from 32 -33%. Therefore requiring minimum cement content to make a good concrete paste.

b) Irregular (or) Partly rounded aggregate

These aggregates are naturally irregular or partly shaped by attrition and have rounded edges. Pit sand and gravels are the good examples of irregular aggregate.

These aggregates are having a higher percentage of voids ranging from 35 – 38%. Thus, the cement required to make a good concrete paste is higher than the cement required for rounded aggregate.

C) Angular aggregate

These aggregates are having well-defined edges. Crushed rocks are a good example of this type of aggregate.

These aggregates are having the maximum percentage of voids ranging from 38 – 40%. Thus the cement required will be higher than the above two.

d) Flaky aggregate

A flaky aggregate is an aggregate where the thickness of the aggregate is small relative to its length and width.

The aggregate is said to be flaky when its least dimension (thickness) is three-fifth of its mean dimension.

The mean dimension of the aggregate is the average of the sieve sizes through which the aggregates passed and retained, respectively.

The flakiness of an aggregate is tested using a “Thickness gauge”.

Let’s understand clearly through an example,

Imagine we have a sample of coarse aggregate which passes through 4.75 mm and is retained on a 20 mm sieve.

Now, the mean dimension of the sample is (4.75+20)/2 = 12.3 mm.

An aggregate in that sample, which is having a thickness of less than 3/5 x 12.3 = 7.38 mm, is called a flaky aggregate.

e) Elongated aggregate

An aggregate is said to be elongated when its greatest dimension (length) is greater than 1.8 times its mean dimension.

The length of the aggregates are tested using a “Length gauge”.

Now, as we see all the classifications, let’s answer a major question that arises in our minds.

Which shape of aggregate is best for making concrete?

There has been a lot of controversy on the subject whether angular aggregate or rounded aggregate will make better concrete.

Rounded aggregates are having minimum voids range, thus the cement required to make a good quality paste will be minimum. Hence economically, it is better to use rounded aggregates. The use of rounded aggregates will also increase the workability of the concrete.

But some engineers avoid the usage of rounded aggregates because of the lack of interlocking of aggregates due to the smooth texture. However, some researchers are denying it by indicating that the roughness in the smooth texture is reasonably enough for good bonding between the aggregates and cement gel.

The angular aggregates are superior to rounded aggregates from the following three points of view:

- Angular aggregates exhibit a better interlocking effect. Hence widely used in making high-strength concrete.

- Angular aggregates are having greater surface area than rounded aggregates. Hence show higher bond strength than the rounded aggregates.

- Since the angular aggregates are having higher voids ratio, the additional cement required will also offer some additional strength to the concrete.

Shortly,

- From an economic and workability point of view – Rounded aggregates are preferred to angular aggregates.

- From the strength point of view – Angular aggregates are preferred to rounded aggregates.

Hope you get all the information you need to know about the classification of aggregates. If you find this article helpful or if you have any queries, let us know in the comment section.

Read more : 5 Types of level used in levelling, Levelling, PPC vs OPC.

The subject on Aggregates quite comprehensive and informative. No regrets reading the topic. Infact really energized my day and week.

Expecting more from your stable. However can you give out your own understanding on the topic of Fine Modulus of Aggregates.

Thanks for your response and help

I’m glad you found this article informative. Your enthusiasm is contagious. I will definitely share my insights about the topic of fineness modulus soon. Stay tuned!